Page 18 - Dentity_EN_0910_high

P. 18

DR MARY O'DONNELL

INFECTION

PREVENTION

18 APPLICATIONS IN

DENTAL UNITS

Dental units use water to cool and irrigate

dental instruments such as high-speed

handpieces and ultrasonic scalers and to

provide water for patient oral rinsing and

cuspidor flushing. Water is supplied to all

dental unit water outlets by a network of

narrow-bore, flexible plastic tubing called

dental waterlines.

These waterlines always become

contaminated with micro-organisms

(mostly bacteria) present in small numbers

in dental unit supply water, where they

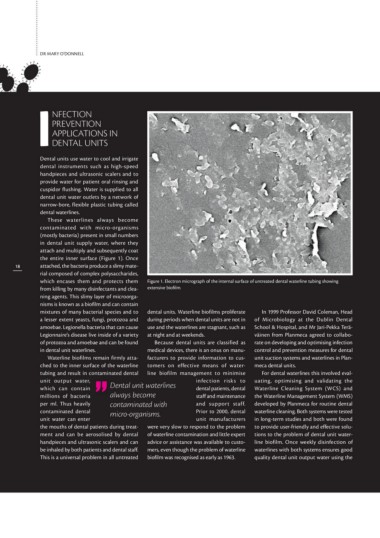

attach and multiply and subsequently coat

the entire inner surface (Figure 1). Once

attached, the bacteria produce a slimy mate-

rial composed of complex polysaccharides,

which encases them and protects them Figure 1. Electron micrograph of the internal surface of untreated dental waterline tubing showing

from killing by many disinfectants and clea- extensive biofilm.

ning agents. This slimy layer of microorga-

nisms is known as a biofilm and can contain

mixtures of many bacterial species and to dental units. Waterline biofilms proliferate In 1999 Professor David Coleman, Head

a lesser extent yeasts, fungi, protozoa and during periods when dental units are not in of Microbiology at the Dublin Dental

amoebae. Legionella bacteria that can cause use and the waterlines are stagnant, such as School & Hospital, and Mr Jari-Pekka Terä-

Legionnaire’s disease live inside of a variety at night and at weekends. väinen from Planmeca agreed to collabo-

of protozoa and amoebae and can be found Because dental units are classified as rate on dev eloping and optimising infection

in dental unit waterlines. medical devices, there is an onus on manu control and prevention measures for dental

Waterline biofilms remain firmly atta- facturers to provide information to cus unit suction systems and waterlines in Plan-

ched to the inner surface of the waterline tomers on effective means of water- meca dental units.

tubing and result in contaminated dental line biofilm management to minimise For dental waterlines this involved eval

unit output water, Dental unit waterlines infection risks to uating, optimising and validating the

which can contain always become dental patients, dental Waterline Cleaning System (WCS) and

millions of bacteria staff and maintenance the Waterline Management System (WMS)

per ml. Thus heavily contaminated with and support staff. developed by Planmeca for routine dental

contaminated dental micro-organisms. Prior to 2000, dental waterline cleaning. Both systems were tested

unit water can enter unit manufacturers in long-term studies and both were found

the mouths of dental patients during treat- were very slow to respond to the problem to provide user-friendly and effective solu-

ment and can be aerosolised by dental of waterline contamination and little expert tions to the problem of dental unit water-

handpieces and ultrasonic scalers and can advice or assistance was available to custo- line biofilm. Once weekly disinfection of

be inhaled by both patients and dental staff. mers, even though the problem of waterline waterlines with both systems ensures good

This is a universal problem in all untreated biofilm was recognised as early as 1963. quality dental unit output water using the