Page 8 - pakoputkistot_busseille

P. 8

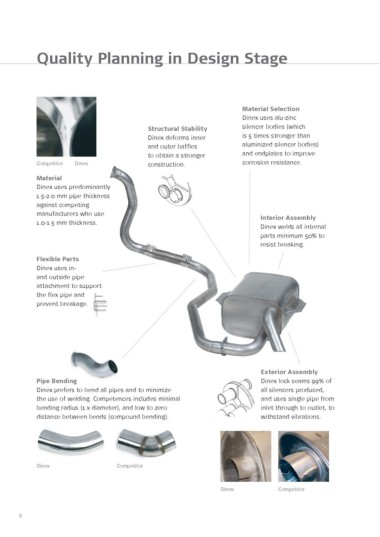

Quality Planning in Design Stage

Competitor Dinex Structural Stability Material Selection

Dinex deforms inner Dinex uses alu-zinc

Material and outer baffles silencer bodies (which

Dinex uses predominantly to obtain a stronger is 5 times stronger than

1.5-2.0 mm pipe thickness construction. aluminized silencer bodies)

against competing and endplates to improve

manufacturers who use corrosion resistance.

1.0-1.5 mm thickness.

Interior Assembly

Flexible Parts Dinex welds all internal

Dinex uses in- parts minimum 50% to

and outside pipe resist breaking.

attachment to support

the flex pipe and

prevent breakage.

Pipe Bending Exterior Assembly

Dinex prefers to bend all pipes and to minimize Dinex lock seams 99% of

the use of welding. Competences includes minimal all silencers produced,

bending radius (1 x diameter), and low to zero and uses single pipe from

distance between bends (compound bending). inlet through to outlet, to

withstand vibrations.

Dinex Competitor

8

Dinex Competitor