Page 11 - ngk-venetulpat

P. 11

ALSO AS VIDEO

IMPORTANT TIPS FOR THE INSTALLATION

OF SPARK PLUGS

A torque wrench is required for the handle. Most spark plug failures can be or warp. Heat dissipation zones are

professional installation of a spark plug. traced back to an incorrect tightening disrupted, overheating and melting of

Even for professionals the estimation of torque. If it is set too low, there is a risk the electrodes or even engine damage

the tightening torque is nearly impossible. of compression losses and overheating. can occur.

That is because a torque can be A break of the insulator or middle

calculated from two sizes which are electrode as a result of vibrations is

multiplied by one another: the force also feasible. If the tightening torque

which is applied to the respective is set too high, the spark plug can

centre of rotation and the length of the snap off. The casing can also expand

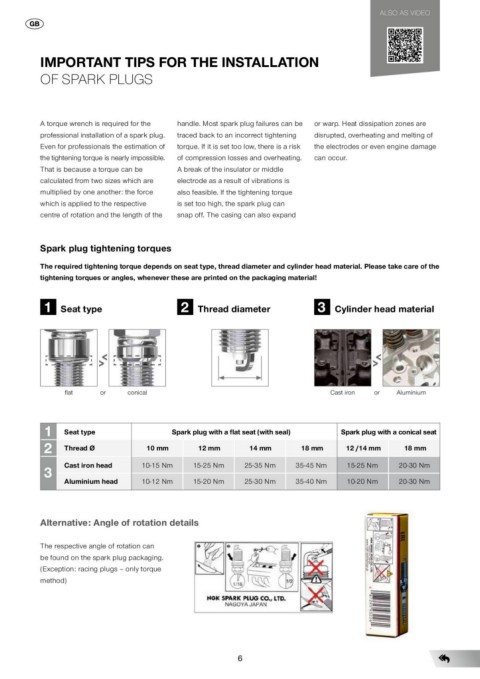

Spark plug tightening torques

The required tightening torque depends on seat type, thread diameter and cylinder head material. Please take care of the

tightening torques or angles, whenever these are printed on the packaging material!

1 Seat type 2 Thread diameter 3 Cylinder head material

flat or conical Cast iron or Aluminium

1 Seat type Spark plug with a flat seat (with seal) Spark plug with a conical seat

2 Thread Ø

3 Cast iron head 10 mm 12 mm 14 mm 18 mm 12 /14 mm 18 mm

Aluminium head 10-15 Nm 15-25 Nm 25-35 Nm 35-45 Nm 15-25 Nm 20-30 Nm

10-12 Nm 15-20 Nm 25-30 Nm 35-40 Nm 10-20 Nm 20-30 Nm

1AlternSaetaitvteyp:eAngle of rotation dSeptaarkilpslug with a flat seat (with seal) Spark plug with a conical seat

2 Thread Ø 10 mm 12 mm 14 mm 18 mm 14 mm 18 mm

The respective angle of rotation can

3be founAdnognlethoef srpoatarktiopnlu, g packaging. ½ turn: 180° ½ – 2/3 turn: 180°–240° 1/16 turn: 22.5°

(Exceptircoeyngli:anrrdadeclerinshgsepaoldfutghse– only torque

methodm) aterial

6