Page 61 - ngk-pienkonetulpat

P. 61

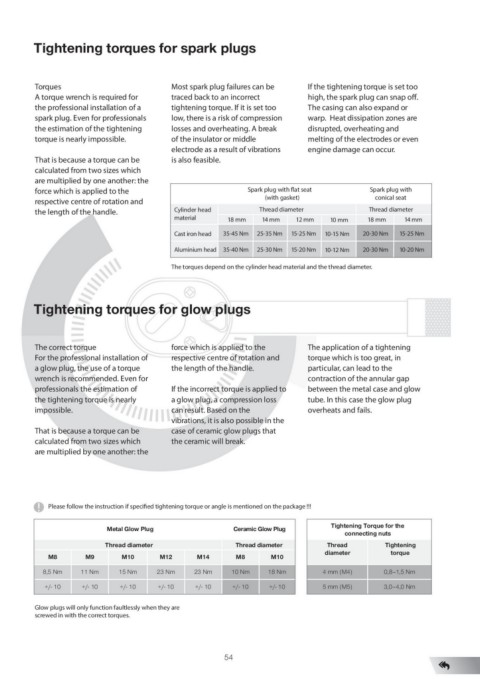

Tightening torques for spark plugs

Torques Most spark plug failures can be If the tightening torque is set too

A torque wrench is required for traced back to an incorrect high, the spark plug can snap o .

the professional installation of a tightening torque. If it is set too The casing can also expand or

spark plug. Even for professionals low, there is a risk of compression warp. Heat dissipation zones are

the estimation of the tightening losses and overheating. A break disrupted, overheating and

torque is nearly impossible. of the insulator or middle melting of the electrodes or even

electrode as a result of vibrations engine damage can occur.

That is because a torque can be is also feasible.

calculated from two sizes which

are multiplied by one another: the Spark plug with at seat Spark plug with

force which is applied to the (with gasket) conical seat

respective centre of rotation and

the length of the handle. Cylinder head Thread diameter Thread diameter

material

18 mm 14 mm 12 mm 10 mm 18 mm 14 mm

Cast iron head

35-45 Nm 25-35 Nm 15-25 Nm 10-15 Nm 20-30 Nm 15-25 Nm

Aluminium head 35-40 Nm 25-30 Nm 15-20 Nm 10-12 Nm 20-30 Nm 10-20 Nm

The torques depend on the cylinder head material and the thread diameter.

Tightening torques for glow plugs

The correct torque force which is applied to the The application of a tightening

For the professional installation of respective centre of rotation and torque which is too great, in

a glow plug, the use of a torque the length of the handle. particular, can lead to the

wrench is recommended. Even for contraction of the annular gap

professionals the estimation of If the incorrect torque is applied to between the metal case and glow

the tightening torque is nearly a glow plug, a compression loss tube. In this case the glow plug

impossible. can result. Based on the overheats and fails.

vibrations, it is also possible in the

That is because a torque can be case of ceramic glow plugs that

calculated from two sizes which the ceramic will break.

are multiplied by one another: the

Please follow the instruction if specified tightening torque or angle is mentioned on the package !!!

Metal Glow Plug Ceramic Glow Plug Tightening Torque for the

connecting nuts

Thread diameter Thread diameter Thread Tightening

M8 M10 diameter torque

M8 M9 M10 M12 M14

8,5 Nm 23 Nm

+/- 10 11 Nm 15 Nm 23 Nm +/- 10 10 Nm 18 Nm 4 mm (M4) 0,8–1,5 Nm

5 mm (M5) 3,0–4,0 Nm

+/- 10 +/- 10 +/- 10 +/- 10 +/- 10

Glow plugs will only function faultlessly when they are

screwed in with the correct torques.

54