Page 7 - dantonit-brochure-naturprodukter-a4-en-lr

P. 7

Natural membranes, landfills and watercourses

There are two methods to choose from: laying and DantoCrude is also used in connection with water-

compacting DantoCrude on a solid surface or milling based infrastructure and areas of environmental

DantoCon Seal N into the existing subsoil to create concern for:

what is known as a milled membrane. A more detailed

work description can be found at www.dantonit.dk • Sealing dikes and dams.

More bentonite is used for a DantoCrude membrane • Retention of leachate in landfills.

than for the milled membrane. However, a DantoCrude • Enclosure of oil and chemical storage facilities.

membrane has lower permeability and saves on the • Management of surface water from landfill slopes.

cost of milling bentonite into the subsoil or a sand layer.

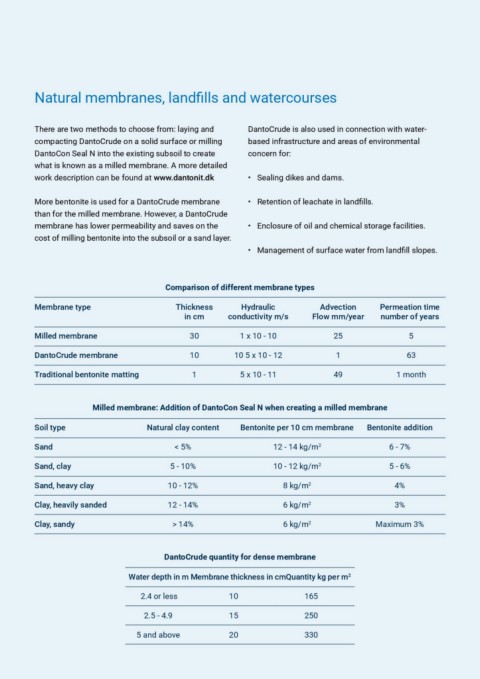

Comparison of different membrane types

Membrane type Thickness Hydraulic Advection Permeation time

in cm conductivity m/s Flow mm/year number of years

Milled membrane 30 1 x 10 - 10 25 5

DantoCrude membrane 10 10 5 x 10 - 12 1 63

Traditional bentonite matting 1 5 x 10 - 11 49 1 month

Milled membrane: Addition of DantoCon Seal N when creating a milled membrane

Soil type Natural clay content Bentonite per 10 cm membrane Bentonite addition

Sand < 5% 12 - 14 kg/m2 6 - 7%

Sand, clay 5 - 10% 10 - 12 kg/m2 5 - 6%

Sand, heavy clay 10 - 12% 8 kg/m2 4%

Clay, heavily sanded 12 - 14% 6 kg/m2 3%

Clay, sandy > 14% 6 kg/m2 Maximum 3%

DantoCrude quantity for dense membrane

W ater depth in m Membrane thickness in cm Quantity kg per m2

2.4 or less 10 165

2.5 - 4.9 15 250

5 and above 20 330